It should be noted here that continuous CF with FDM is not new, as Markforged already does something similar, though at a ‘Contact us for a price quote’ level. The advantage of the Fibre Seek solution is then the co-extrusion that would make printing with continuous CF much more flexible and affordable. Based on the (sponsored) [CNC Kitchen] video of a few weeks ago at a tradeshow, the FibreSeeker 3 printer is effectively a standard CoreXY FDM printer, with the special co-extrusion dual print head that allows for CF to be coated with the target thermoplastic before being printed as normal.

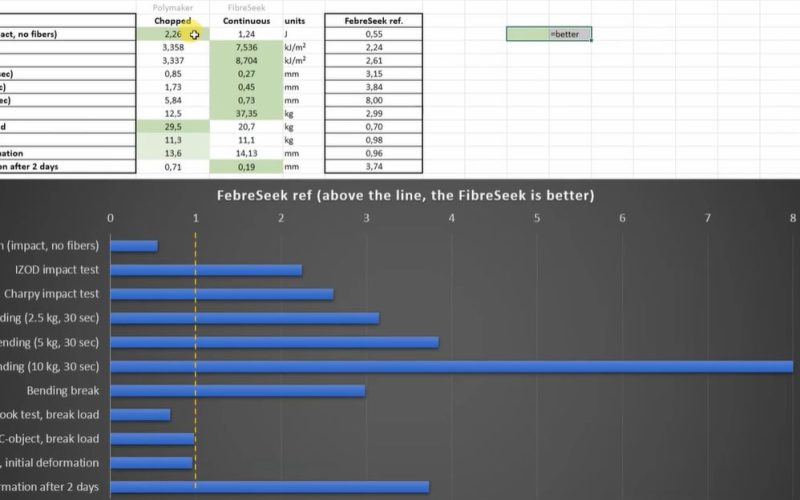

Unfortunately for [Igor] he did not have a FibreSeeker 3 to print on, and the print request for his usual test samples got mixed up by Fibre Seek, leaving him with only 4 out of 10 items to test with. This makes this a bit of an abbreviated test, but should still provide some useful data relative to the Polymaker PETG-CF filament that was used for comparison.

Based on the limited test set, it can be said that the FibreSeeker 3 parts did generally better than the PETG-CF parts, albeit with a few asterisks. Accordingly, [Igor] is left feeling somewhat confused by Fibre Seek, but sees the potential of this new co-extrusion technology. It just feels like the FibreSeeker 3 printer is not quite finished yet, and that the true value of this approach and this new printer will have to prove themselves.