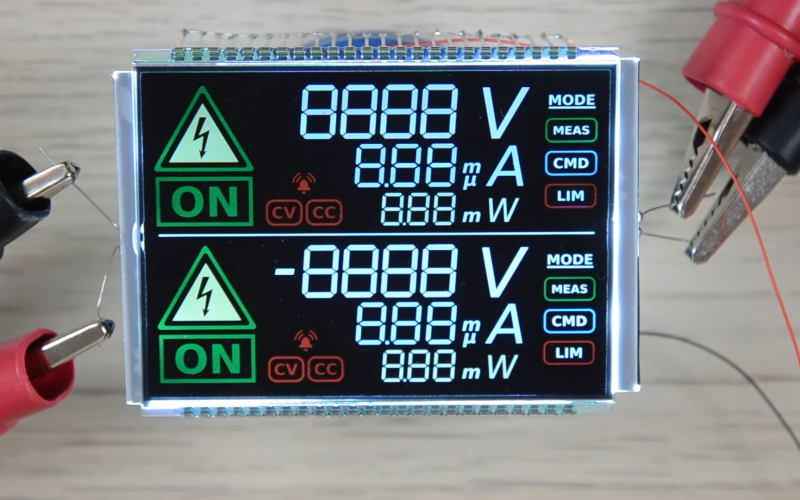

These days, you can buy full graphical LCD or OLED displays for just a few dollars. However, if you’re so inclined, you can actually get your own segmented LCDs made to suit your own projects. [Icoso Labs] explains how it’s done, with plenty of handy tips along the way.

There are three primary things you need to do to design a segmented LCD. First, you need to design it visually, laying out all the individual elements you want on the display. Then you need to determine how you want to split them up into segments. Some elements you’ll just want to be a single monolithic on-or-off shape, while other areas you might want to create things like seven-segment numerals for displaying numbers and so on. With that done, you also need to specify various engineering details—such as whether you want a transmissive, reflective, or transflective display, and thicknesses, colors, and other important things. Armed with all that, you can take your design to a manufacturer and get them to make a bunch for you. Often, there’s a moderately high tooling cost to start a run, but you can then turn out more examples of your design for just a few bucks apiece.

It’s a neat guide to designing something few of us have ever considered sourcing for ourselves. We’ve featured other insights into the world of segmented LCDs before, too. Video after the break.